Is a Brushless Drill Worth It? Honest Cost-Performance Guide

If you're staring at tool aisle shelves wondering is a brushless drill right for your next project, you're not alone. That extra $50-$150 price tag sparks real debate among DIYers and pros alike. Let's cut through the marketing noise with practical, project-tested insights. Because whether you're mounting a TV bracket or framing a shed, the project drives the pick (not the other way around).

Why the Brushless vs. Brushed Confusion?

"I thought I just needed a drill," my neighbor admitted after stripping three drywall anchors during a simple bookshelf install. "Then I saw 'brushless' tags everywhere and froze." Sound familiar? Marketing lingo like "brushless motor efficiency" gets thrown around, but what does it actually mean for your weekend project? If you want the numbers to make sense, see our drill specifications guide.

Let's simplify:

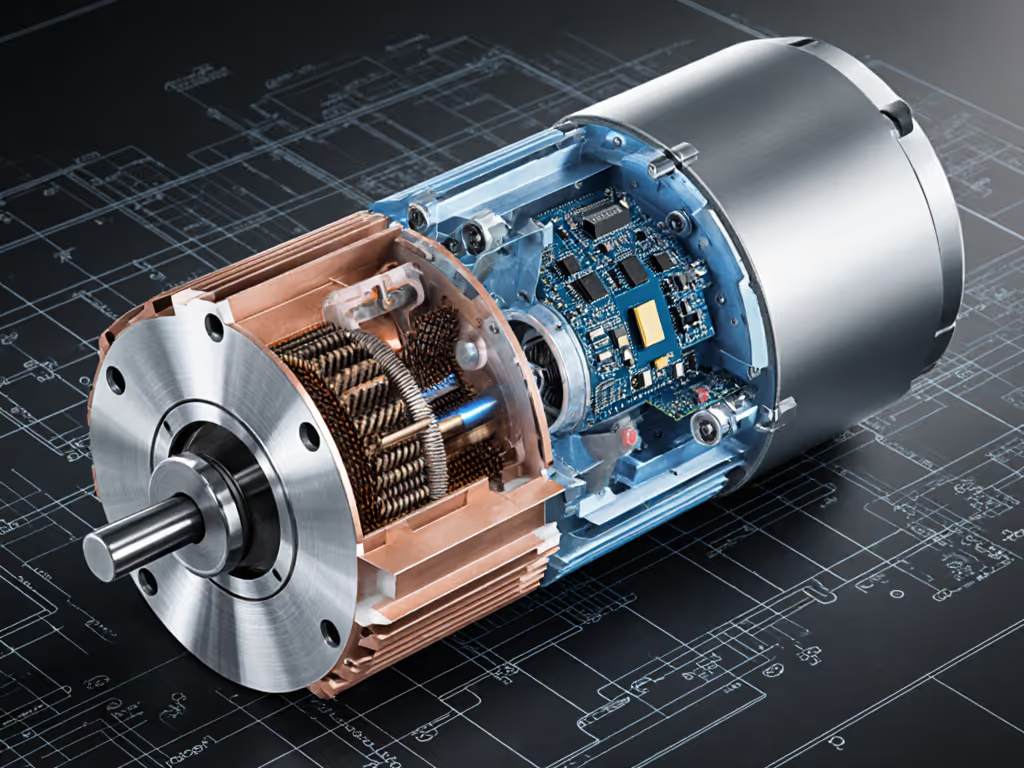

- Brushed drills use carbon blocks (brushes) that physically touch the motor to deliver power. Think of them like a record player needle, simple but wearing down over time.

- Brushless drills replace those physical contacts with smart electronics that precisely control power flow. No touching parts = less wasted energy.

That neighbor? We grabbed her compact brushed drill, dialed the clutch to 8, and pre-marked holes. Three perfect anchors later, she breathed easy. But as she tackled bigger projects, we realized her tool couldn't keep up. This is where brushless might be your next smart step, not because it's "better", but because it solves specific frustrations.

Real Talk: Brushless Motor Efficiency in Your Hands

"Efficiency" sounds like a textbook term until your battery dies mid-project. Here's how brushless motor efficiency actually helps you:

| Scenario | Brushed Drill | Brushless Drill |

|---|---|---|

| Drilling 50 holes in 2x4s | 1.5 battery charges | 1 battery charge |

| Driving 100 deck screws | Noticeable slowdown at hole #75 | Consistent speed through #100 |

| Hot afternoon work | Motor overheats after 20 mins | Runs cooler 30+ mins |

"Brushless isn't about more power: it's about keeping power when the job gets tough."

During a recent pergola build with my contractor friend Luis, his brushless drill finished 200 lag bolts while my older brushed model sputtered at #160. The difference? His tool used electronics to redirect power away from heat buildup. That's brushless motor efficiency in action, translating to fewer battery swaps and less shoulder strain.

Brushed vs. Brushless Cost: What the Price Tag Really Hides

Let's tackle that $100+ price gap head-on. A brushed drill cost comparison needs to look beyond the register:

| Cost Factor | Brushed Drill | Brushless Drill |

|---|---|---|

| Upfront price | $80-$150 | $120-$250 |

| Battery life | 2-3 years (heavy use) | 4-7+ years |

| Repair frequency | Brushes replaced yearly | Electronics rarely serviced |

| Lost time | Slower work + recharging | Fewer interruptions |

I watched a DIY mom, Sarah, buy a $99 brushed drill for kitchen cabinets. By year two, she'd replaced brushes twice ($25 each) and bought extra batteries because runtime shrank. Her total? $170, and she still struggles with hardwood drilling. Meanwhile, her neighbor's $199 brushless handled the same project with one battery charged overnight.

For occasional users (hanging pictures 2-3x yearly), brushed is economical. But if you tackle 5+ projects annually, brushless pays back through:

- Time savings (less recharging/breaking)

- Reliability (no mid-job stalls)

- Battery longevity (maintains capacity longer)

"Is Brushless Worth It" for Beginners? My Hands-On Advice

New DIYers often ask: "Will I even notice the difference?" The answer depends on YOUR projects, not pro YouTube reviews. Here's my starter checklist:

✅ Choose brushed if you:

- Only do light tasks (assembling furniture, shelf brackets)

- Work <10 hours/month

- Already own compatible batteries (avoid platform hopping!)

✅ Choose brushless if you:

- Hit hardwood, tile, or thick lumber regularly

- Get frustrated by slow drilling or battery drain

- Plan to expand your toolkit (saws, sanders etc.)

DEWALT 20V MAX Hammer Drill and Impact Driver Combo Kit (DCK299M2)

The DEWALT 20V MAX combo kit I recommended to Sarah hits the sweet spot for growing DIYers. Its brushless motor handles oak trim without bogging down, while the compact head accesses tight cabinet corners, exactly where beginners struggle most.

The "Forgotten" Factor: How Brushless Protects Your Confidence

Remember that neighbor who stripped anchors? Her real issue wasn't the drill, it was losing confidence after early failures. Here's where brushless subtly wins for new users:

- Smooth clutch control: Electronics prevent sudden jolts that strip screws

- Cooler operation: Less heat = safer to hold during extended work

- Consistent torque: No power drop-off as battery drains (critical for delicate materials)

On a recent deck project, my apprentice kept camming out screws with his brushed drill. Switched him to a brushless model with adjustable speed, and suddenly his screw depth was perfect every time. "It just works when I need it to," he said. That reliability? That's how beginners become confident builders.

When Brushless Isn't Worth It (Yes, Really)

Despite the hype, brushless isn't magic. Avoid it if:

- You rarely drain batteries: Brushed models suffice for quick tasks

- You own a strong brushed platform: Adding brushless mid-system creates battery chaos

- Budget is tight now: A $120 brushed drill beats no drill at all

My rule: Start with the project, then match the drill and batteries. That kitchen cabinet job? Brushed was fine. But when Sarah decided to tile her bathroom, we upgraded together, choosing a brushless drill that fit her existing battery system. No wasted gear, no confusion.

Your Smart Upgrade Path: No Regrets, Just Results

So... is brushless worth it? Answer these three questions before buying:

- "What's my next project?" (Not "what might I do someday?")

- Hanging curtains? Stick with brushed.

- Building a shed? Prioritize brushless runtime.

- "How often does my current drill fail me?"

- "Battery dies constantly" = brushless efficiency will help

- "Only struggles with hardwood" = consider brushless or better bits

- "Will this fit my whole system?"

- Never buy a lone brushless tool if your other gear is brushed

- Start with ONE brushless drill/driver, then expand only as projects demand

The Bottom Line: Confidence Through Clarity

Brushless drills aren't "better"; they're different tools for different jobs. That $200 brushless model isn't worth it if you only need a $100 brushed one. But if you're hitting walls (literally) with slow drilling or dying batteries, the efficiency gains pay for themselves in saved time and frustration.

I've seen too many DIYers buy max-torque brushless kits "just in case", only to feel overwhelmed by complex settings. Don't fall for that. Your goal isn't the fanciest tool, it's finishing projects without that nagging "I wish I had..." feeling.

Your next step: Grab your current drill. Try driving 20 screws into scrap wood similar to your project material. Note where it struggles. That's where brushless might earn its keep, not in specs sheets, but in your hands on a Tuesday afternoon.

Start with the project, then match the drill and batteries.