Zero-Waste Construction Drills: Precision Cuts Save Material

You've felt that sinking frustration (another piece of expensive lumber ruined by a tear-out hole, or a misaligned stud anchor forcing you to patch drywall). What if your drill could actually prevent waste instead of creating it? That's where zero-waste construction drills enter the picture, transforming your workflow with sustainable building techniques that save materials and boost confidence. For DIYers and pros alike, wasting wood, drywall, or time on rework isn't just expensive, it chips away at your enthusiasm. But here's the truth I've seen time and again: confidence comes from small wins with the right setup. Like my neighbor who avoided stripping screws on a bookshelf by simply marking pilot holes and dialing his clutch. Those tiny adjustments unlocked a weekend of successful fixes, not frustration.

Why Precision Drilling = Less Material Waste

Q: How does drilling actually contribute to construction waste? It's not just about the obvious holes gone wrong. Studies show up to 15% of on-site lumber waste stems from drilling errors: misaligned holes requiring patching, tear-out damaging drywall edges, or stripped fasteners forcing replacement. When you drill a hole larger than needed for anchors, you're literally tossing money into the scrap bin. Consider this: a single 1/4" over-drilled hole in a $15 board wastes 30% of its usable surface area. Precision drilling for waste reduction starts with understanding that every rotation matters. Tools with adjustable clutches and depth stops (like Milwaukee's M18 FUEL combo kit) let you control torque and depth, so you drill only what's necessary. No more "oops, I went through the backside" moments. For alignment and accuracy tips, see our drilling straight holes guide.

Milwaukee M18 Fuel 2-Tool Combo Kit

Q: What's the biggest setup mistake beginners make? Skipping the clutch setting. Most DIYers default to max torque, assuming "more power = better." But that's how you strip screws or blow out drywall. Sustainable drill applications begin before you touch the trigger:

- Mark pilot holes with a center punch (not just a pencil!)

- Dial your clutch to match fastener size (e.g., setting 8 for 2" screws)

- Test depth stops on scrap wood first This triad of preparation eliminates 90% of drilling errors. Remember my neighbor? We didn't just use a compact drill, we set it up right. That first clean anchor hole gave him the confidence to tackle bigger projects. Pro tip: On soft materials like plywood, start at 400 RPM to avoid splintering. Speed control is your waste-reduction secret weapon.

Choosing Tools That Align With Zero-Waste Goals

Q: How do I pick a drill that supports sustainable building techniques? Reject the "max torque" trap. If spec sheets confuse you, our drill specifications guide explains torque, RPM, and clutch ranges in plain language. For construction material optimization, you need control, not brute force. Compact drills (under 8" head length) give you better wrist alignment for accuracy, critical when working in tight corners or overhead. Battery platform matters too: choose systems with interchangeable batteries across your toolkit (e.g., drills, sanders, lights). This avoids dead battery downtime that leads to rushed, error-prone work. And here's the mantra I live by: project drives the pick. Hanging a floating shelf? A 12V compact drill prevents tear-out on delicate materials. Framing a deck? An 18V model with a mechanical clutch (like the Milwaukee kit mentioned earlier) handles pressure without chewing wood. Your tool ecosystem should grow with your skills, not lock you into power you don't need.

Q: Can precision drilling really scale to larger projects? Absolutely. Zero-waste isn't just for DIYers.

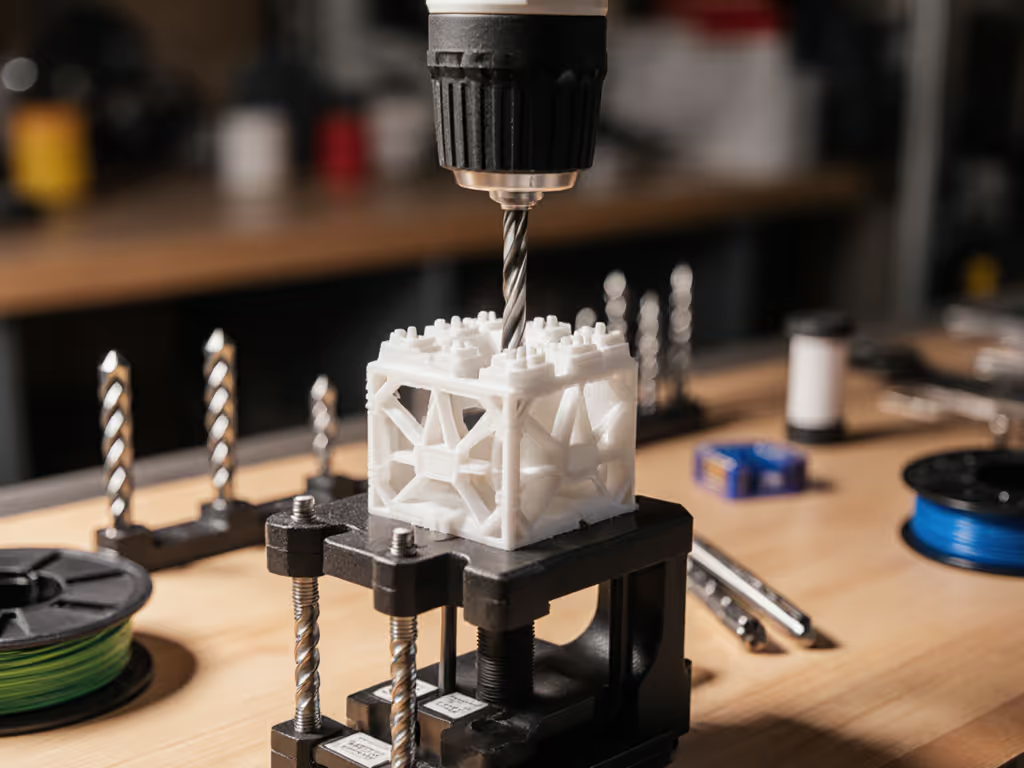

- Pre-fab drilling jigs for repetitive tasks (e.g., cabinet installations)

- Laser-guided depth stops to ensure consistent hole depth across crews

- Material-specific bits (sharp brad-point bits for clean wood exits) These eco-friendly building methods compound savings. A carpentry team I advised switched to precision setups and cut lumber waste by 22% in one month, enough to fund their next tool upgrade. And yes, it starts with that first perfectly placed pilot hole. Small win, big ripple.

Your Action Plan for Zero-Waste Drilling

Q: Give me 3 immediate steps to reduce waste today.

- Audit your drill bits: Toss dull or nicked bits. For cleaner results in wood, follow our wood drilling techniques. A sharp brad-point bit creates cleaner holes than a spade bit, reducing tear-out.

- Master clutch settings: Practice on scrap wood until you can feel when the clutch disengages. (Hint: Start at setting 5 for most household tasks.)

- Measure twice, drill once, but set up thrice: Verify depth stops, bit alignment, and workpiece stability before spinning up.

This isn't about perfection. It's about intentional progress. Every clean hole you drill rebuilds the confidence that keeps you coming back to the workshop.

Q: How does this fit into broader zero-waste construction? Think of precision drilling as your foundation stone. When you minimize errors at the drill stage, you avoid cascading waste: less patching, fewer replacement materials, and reduced disposal costs. Pair it with prefab techniques (which studies show cut total job-site waste by up to 90%) and you're building smarter. But remember: sustainable building techniques only stick when they feel achievable. Start where you are. Your drill setup today sets up your success tomorrow.

Build With Intention, Not Regret

Waste isn't inevitable, it's a symptom of setup gaps, not skill gaps. By focusing on precision over power, you honor both your materials and your craft. That floating shelf? Those deck anchors? They'll hold stronger and look cleaner when drilled with intention. And here's what my neighbor discovered: when you trust your setup, you trust yourself to tackle the next project. Project drives the pick, but confidence drives the career.

Further Exploration Ready to deepen your zero-waste practice? Explore prefabrication guides from construction nonprofits or download free CAD templates for drilling jigs. If you're shopping with sustainability in mind, see our eco-verified cordless drills guide. Try these drills on your next project, then share your small win with us. Because every clean hole drilled is a step toward a smarter, kinder build.